五五世纪Quick navigation

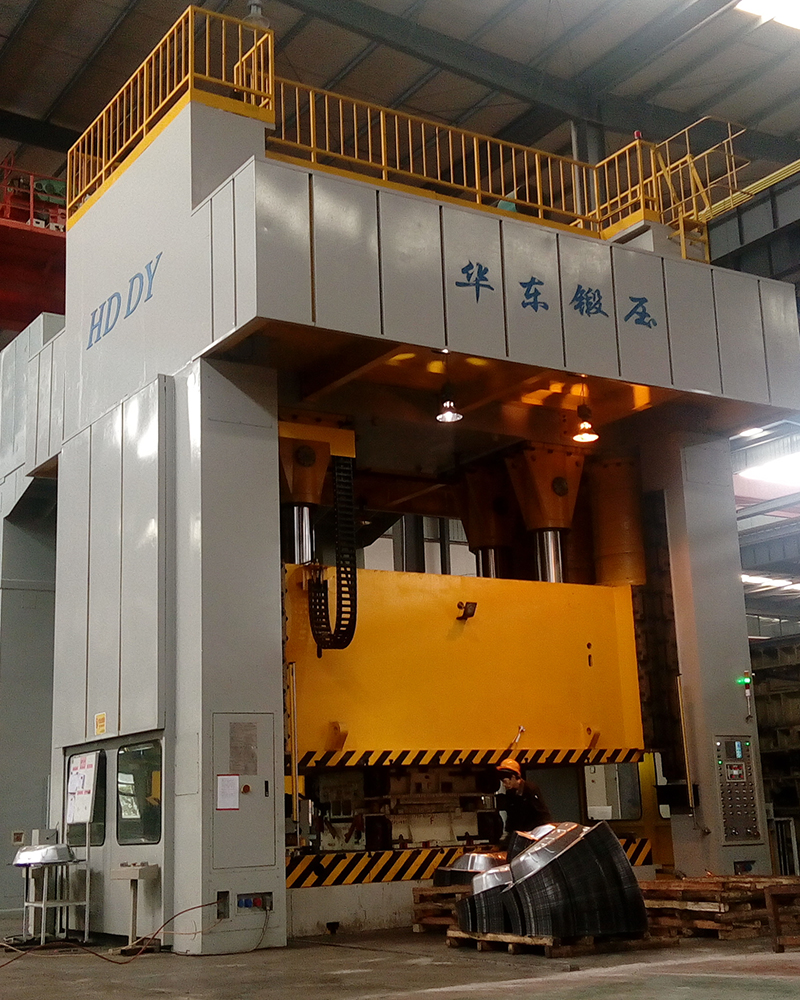

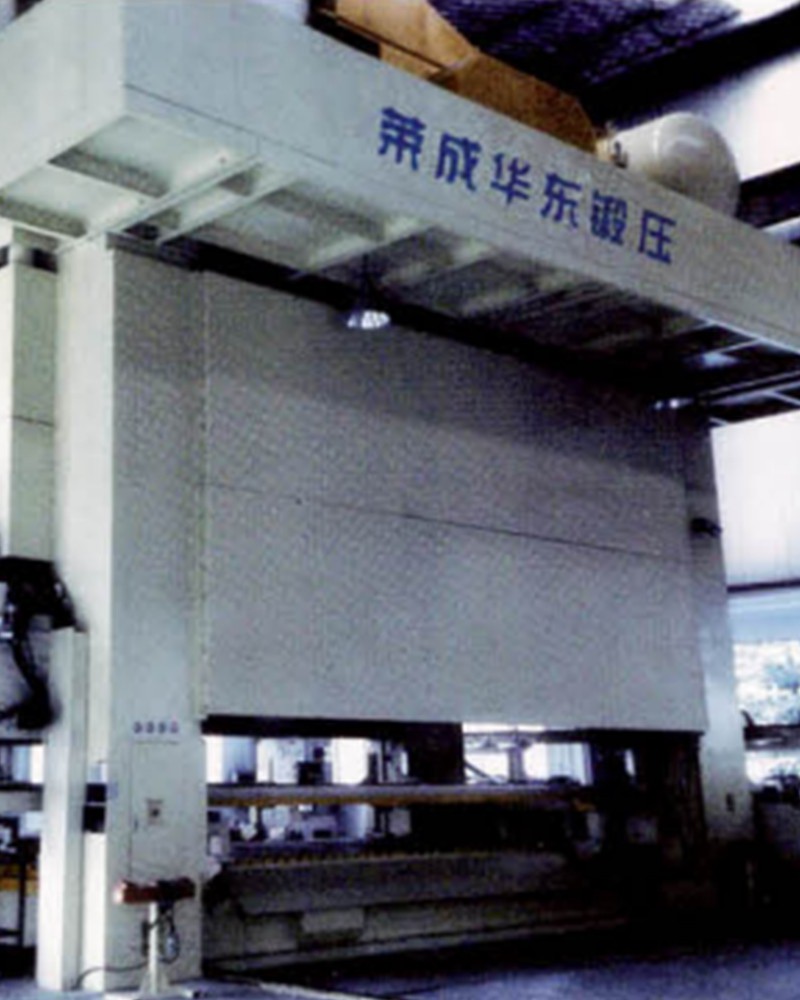

J39系列闭式四点单动机械压力机

J39 series straight-side four point press

主要功能和特点:

Main Structure Features:

·全钢板焊接分体式机身,由底座、立柱、横梁三大件通过4根拉紧螺栓预紧成一体,横梁与滑块之间采用导柱导套方式过渡连接

Detachable steel welded frame with high rigidity, welded crown,column and bed are pretightened with tie rod bolt, transition connected by adopting guide pillar and bush between crown and slider

偏心齿轮轴式结构,滑块行程大 ,承载能力强

It has eccentric gear spindle structure, which has large slider stroke and strong carryng capacity

四角超长导轨导向,保证运行精度

Eeight-face rectangle guide of slide ensures running accuracy

干式气动分体式离合器、制动器,结合、制动力矩大,寿命长、低噪音、维修方便

Part revolusion pneumatic friction clutch and brake , with large braking torque, long service life, low noise and convenient for maintenance

液压过载保护装置,过载自动紧急停车,保护压力机及模具的安全

Hydraulic overload protection device and overload automatic emergency stop, protect press and mold safety

稀油自动润滑系统,具有油路报警功能

Automatic oil lubricating system, functioning of oil circuit alarm

PLC电气集中控制,具有急停、寸动、单次、连续操作规范;带触摸屏显示调整功能

PLC electrical centralized control, functioning of emergency stop,fine adjustment, single and continuous operational action; with functioning of touchscreen display and adjustment

装模高度电动调节,数字及触摸屏显示

Electrical adjustment of die set height with digital and touchscreen display

可根据需要选配吨位仪、上模夹紧器 、减震垫、气垫(可增加气垫行程可调及闭锁功能)等装置。

Optional:tonnage,die holding device ,buffer and air cushion (air cushion stroke adjustable and closing function can be added)

|

型号(type) 参数(Specification) |

JC39-500A |

JB39-630B |

JC39-630 |

JA39-800E |

JA39-800F |

JF39-1000 |

J39-1250 |

JF39-1600 |

JF39-2000 |

|||

|

公称力(千牛) Nominal pressure(KN) |

5000 |

6300 |

6300 |

8000 |

8000 |

10000 |

12500 |

16000 |

20000 |

|||

|

公称力行程(毫米) Nominal pressure stoke(mm) |

13 |

13 |

13 |

13 |

13 |

13 |

13 |

13 |

13 |

|||

|

滑块行程长度(毫米) Slide stroke(mm) |

700 |

700 |

800 |

800 |

800 |

850 |

800 |

800 |

800 |

|||

|

滑块行程次数(次/分钟) Strokes of slide(spm) |

8-18 |

10-16 |

8-18 |

16 |

16 |

10-16 |

10-18 |

8-15 |

8-13 |

|||

|

微调行程次数(次/分钟) Trimming strokes(spm) |

3-6 |

3-6 |

3-6 |

/ |

/ |

3-6 |

3-6 |

3-6 |

3-6 |

|||

|

最大装模高度(毫米) Max. die height(mm) |

1200 |

1300 |

1600 |

1400 |

400 |

1350 |

1200 |

1400 |

1400 |

|||

|

装模高度调节量(毫米) Die height adjustment(mm) |

600 |

600 |

700 |

600 |

600 |

600 |

600 |

600 |

600 |

|||

|

导轨间距离(毫米) Distance between gilbs(mm) |

4100 |

4100 |

4600 |

4710 |

5110 |

4610 |

5100 |

5600 |

5600 |

|||

|

滑块尺寸(毫米) Slide area(mm) |

前后F.B |

2000 |

2200 |

2200 |

2500 |

2500 |

2200 |

2500 |

2600 |

2500 |

||

|

左右L.R |

4000 |

4000 |

4500 |

4600 |

5000 |

4500 |

5000 |

5500 |

5500 |

|||

|

工作台板尺寸 (毫米) Bolster area(mm) |

前后F.B |

2000 |

2200 |

2200 |

2500 |

2500 |

2200 |

2500 |

2600 |

2500 |

||

|

左右L.R |

4000 |

4000 |

4500 |

4600 |

5000 |

4500 |

5000 |

5500 |

5500 |

|||

|

厚度TH |

260 |

260 |

280 |

300 |

320 |

300 |

300 |

320 |

350 |

|||

|

气垫(Cushion) (选配) (Optional) |

数量(个) Qty(Piece) |

单顶冠 |

单顶冠 |

/ |

单顶冠 |

单顶冠 |

/ |

单顶冠 |

单顶冠 |

单顶冠 |

||

|

气垫力(千牛) Capacity(KN) |

750 |

1200 |

/ |

1500 |

1500 |

/ |

2500 |

2000 |

3000 |

|||

|

行程(毫米) Stroke(mm) |

10-250 |

15-300 |

/ |

0-300 |

0-300 |

/ |

10-300 |

15-300 |

15-300 |

|||

|

工作台移动方式 Move mode of the bolster |

前移 Forward |

左右移 L.R |

左右移 L.R |

右移 R |

左右移 L.R |

左右移 L.R |

前移 Forward |

前移 Forward |

前移 Forward |

|||

|

主电机功率(千瓦) Main motor power(KW) |

90 |

110 |

90 |

132 |

132 |

132 |

132 |

250 |

315 |

|||

|

电气控制方式 Electrical control |

PLC |

PLC |

PLC |

PLC |

PLC |

PLC |

PLC |

PLC |

PLC |

|||

|

离合器形式 Shape of air clutch |

气动、分体 Spilt type |

气动、分体 Spilt type |

气动、分体 Spilt type |

气动、分体 Spilt type |

气动、分体 Spilt type |

气动、分体 Spilt type |

气动、分体 Spilt type |

气动、分体 Spilt type |

气动、分体 Spilt type |

|||

|

润滑方式 Lubrication |

稀油润滑 Thin oil |

稀油润滑 Thin oil |

稀油润滑 Thin oil |

稀油润滑 Thin oil |

稀油润滑 Thin oil |

稀油润滑 Thin oil |

稀油润滑 Thin oil |

稀油润滑 Thin oil |

稀油润滑 Thin oil |

|||

|

压机外形尺寸(毫米)Overal dimensions(mm) |

前后F.B |

5180 |

3700 |

4300 |

6000 |

6000 |

6700 |

6580 |

4400 |

4500 |

||

|

左右L.R |

6870 |

6030 |

6600 |

6750 |

7150 |

7570 |

8180 |

8500 |

8800 |

|||

|

压机地面以上尺寸(毫米) Height above floor(mm) |

8250 |

8400 |

8900 |

10000 |

10000 |

10600 |

9600 |

10800 |

11200 |

|||

|

备注 (Remark) |

四立柱式 Four column |

四立柱式Four column |

四立柱式 Four column |

四立柱式 Four column |

四立柱式 Four column |

四立柱式Four column |

四立柱式 Four column |

四立柱式 Four column |

四立柱式 Four column |

|||